News

BANDON's Inseparable Bond with EVI Technology

The development of air source heat pumps has a history of several decades, and to this day, air source heat pump units are becoming more and more popular.However, in the early days of the development of air source heat pumps, due to technical limitations, the heat pumps had their own limitations, that is, they could not operate in a low ambient temperature environment, or the operating effect was poor.

This has greatly limited the popularity of air source heat pumps in the low-temperature areas. In order to overcome this problem, compressor manufacturers who have been deeply involved in the field of air source heat pumps have been continuously conducting technological research and development and updates.

01: Leading the Way, Breakthrough Innovation

More than a decade ago, the world-class compressor brand, which was keen on developing EVI technology. In 2006, Emerson Company of the United States took the lead in establishing the project and started to tackle the research and development.

At that time, he was the project leader of Emerson Company of the United States, responsible for product development and successful market application. He participated in the whole process, and achieved mass production in 2009, breaking the gap in the industry!

In 1998, BANDON's core team had entered the "compressor" industry, which is known as the heart of air source units, and acted as the agent of Emerson Copeland scroll compressors in the United States.

Serving the earliest batch of air source heat pump manufacturers in China. Looking back on the more than ten years of BANDON's history, there are many feelings and heroic spirits. Everyone has a common ambition and is determined to apply the cutting-edge technologies of foreign companies that they have learned, applied and contacted to the domestic market. From suppliers of air source manufacturers to manufacturers of inverter air source units, the core members and co-founders of the team are from the technical centers of Fortune 500 foreign-funded enterprises such as Emerson, Hitachi, and Panasonic.

It is the earliest team in China to master and apply DC inverter control technology and system matching technology.

Decades of technology and experience have accumulated to master the core technology of inverter technology. It has brought reliable operation to consumers. The original intention is the goodness of human nature; the original intention is "to be vigorous and powerful, and to treat the former marquis as dirt", and never forget the love and responsibility for the motherland.

02: EVI Solving Low-temperature Heating

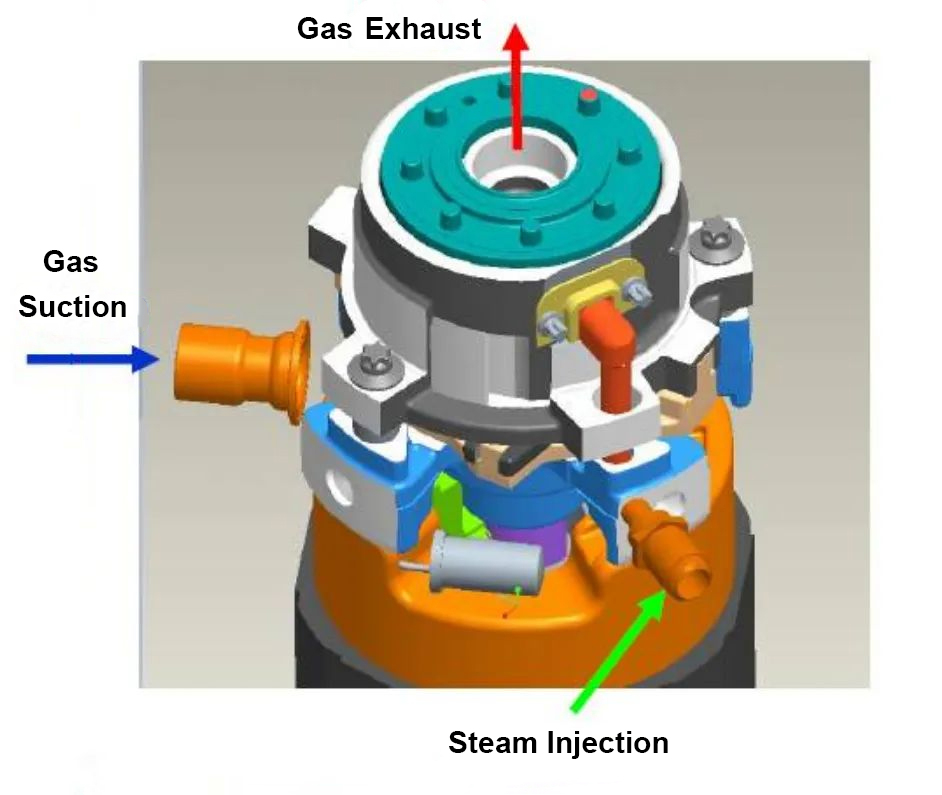

Before understanding the EVI technology, BANDON first talks about the purpose of this technology: it is to solve the problem of low-temperature heating. The EVI compressor adopts two-stage throttling intermediate jet technology and uses a flash evaporator for gas-liquid separation to achieve the enthalpy increase effect.

It achieves the purpose of improving heating capacity in low-temperature environment by compressing and jetting mixed cooling at medium and low pressure, and then compressing normally at high pressure to increase the exhaust volume of the compressor.

The high-efficiency supercooler also plays a key role in the entire system. It supercools the refrigerant in the main circulation loop before throttling to increase the enthalpy difference.

On the other hand, it appropriately preheats the low-pressure and low-temperature refrigerant in the auxiliary loop (this refrigerant will be introduced from the middle of the compressor and directly participate in compression) after the electronic expansion valve reduces the pressure to achieve a suitable medium pressure and provide it to the compressor for secondary compression.

Air source heat pump using EVI technology have two notable features:

1. Energy Saving and High Efficiency

BANDON inverter air source heat pump adopts advanced technology, including EVI system, high-efficiency heat exchanger, efficient fan motor, optimized wind hood design and other technologies. Operating costs during cooling and heating are greatly reduced.

2. Improved Performance in Severe Cold cConditions

BANDON's EVI series products achieve ultra-low temperature heating at -35°C. The technology increases the heating capacity of the compressor in severe cold conditions. The heating capacity is increased by nearly 20%-50% at -15℃.

When the outdoor temperature is very low, the heat exchange capacity of the outdoor unit decreases, the return air volume of the normal air return port of the compressor decreases, the compressor power decreases, and the best effect cannot be achieved.

However, the refrigerant gas is replenished through the intermediate pressure return air injection port, thereby increasing the compressor exhaust volume, and the amount of circulating refrigerant for heating in the indoor unit heat exchanger increases, thereby achieving an increase in heating capacity. Therefore it is more suitable for cold areas.

RELATED NEWS

- India: Coal Production to more than Double by 2020

- The 2023 China Clean Energy and Environmental Protection Expo

- Russian Man Sells Nuclear Weapons Materials across Borders

- Four Japanese Power Companies will Cooperate in the Field of Nuclear Power Safet

- Forecast Analysis of Japanese Nuclear Power Generation and Energy Crisis